Learn more about cable insulation.

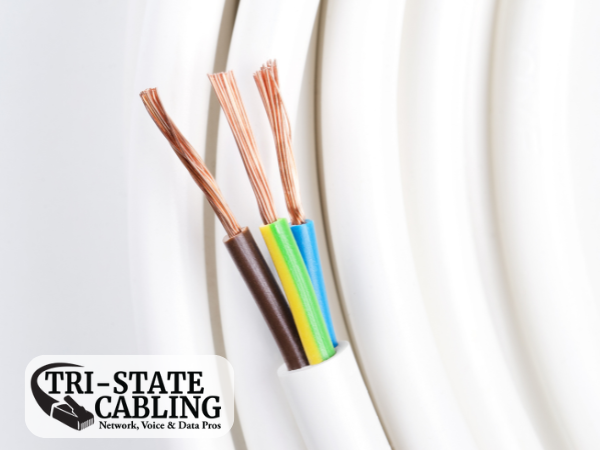

Cable insulation refers to the protective layer that surrounds the conductive material (such as copper or aluminum) within a cable. This insulating layer is typically made from non-conductive materials like rubber, plastic, or a combination of various polymers. The primary purpose of this insulation is to prevent electrical currents from escaping the cable, ensuring that electricity or data flows efficiently from one point to another without interference or loss.

What Does Cable Insulation Do?

Cable insulation serves several critical functions that are vital for the safe and efficient operation of electrical and telecommunications systems. Here are the main roles that cable insulation plays:

Electrical Isolation

The most fundamental role of cable insulation is to electrically isolate the conductive material within the cable. This prevents electrical currents from escaping and potentially causing short circuits, which can lead to equipment damage, fire hazards, or even personal injury.

Protection from Physical Damage

Insulation protects the delicate conductive core from physical damage that can occur due to abrasion, moisture, chemicals, and other environmental factors. This ensures the longevity and reliability of the cable, even in harsh conditions.

Prevention of Signal Interference

In telecommunications and data transmission, insulation helps prevent signal interference. Proper insulation minimizes crosstalk between cables and reduces electromagnetic interference (EMI), ensuring that data is transmitted accurately and efficiently.

Safety Enhancement

Cable insulation enhances overall safety by preventing accidental contact with live wires. This is particularly important in residential and commercial settings, where exposed wires can pose serious risks to people.

Types of Cable Insulation Materials

Different applications require different types of insulation materials. The choice of material depends on factors such as the operating environment, temperature range, and specific performance requirements. Here are some common types of cable insulation materials:

PVC (Polyvinyl Chloride)

PVC is one of the most widely used insulation materials due to its versatility, durability, and cost-effectiveness. It offers good electrical insulation, chemical resistance, and flame retardancy, making it suitable for a wide range of applications.

PE (Polyethylene)

Polyethylene insulation is known for its excellent electrical properties, moisture resistance, and low dielectric constant. It is commonly used in high-frequency and high-voltage applications, such as coaxial cables and power transmission lines.

XLPE (Cross-linked Polyethylene)

XLPE insulation provides superior thermal and mechanical properties compared to regular polyethylene. It is used in applications that require high-temperature resistance and greater durability, such as underground power cables.

Rubber

Rubber insulation, including natural rubber and synthetic variants like neoprene, offers flexibility, elasticity, and good electrical insulation properties. It is often used in flexible cables, portable cords, and applications that require resistance to abrasion and environmental factors.

Teflon (PTFE)

Teflon insulation is known for its excellent heat resistance, chemical inertness, and low friction properties. It is commonly used in high-temperature and high-frequency applications, such as aerospace and military cables.

Importance of Choosing the Right Cable Insulation

Selecting the appropriate insulation material is crucial for ensuring the performance, reliability, and safety of your cabling system. Here are some factors to consider when choosing cable insulation:

- Operating Environment: Consider the environmental conditions the cable will be exposed to, such as temperature, moisture, and chemical exposure.

- Electrical Requirements: Ensure the insulation material can handle the voltage and current levels of your application.

- Mechanical Properties: Evaluate the flexibility, durability, and resistance to physical damage required for your specific use case.

- Regulatory Compliance: Ensure the chosen insulation material meets relevant industry standards and safety regulations.

Contact Tri-State Cabling for Cabling and Grounding

Cable insulation and management are vital components of any electrical or telecommunications system, providing essential protection and ensuring efficient, safe, and reliable operation. Understanding what cable insulation is and what it does can help you make informed decisions when selecting cables for your specific needs. At Tri State Cabling, we are committed to providing high-quality cabling solutions with the right insulation materials to meet your requirements.

Contact us today to learn more about our products and how we can help you with your cabling needs.